Warehouse Management System

Are you struggling with inaccurate inventory, inefficient picking, and costly shipping errors? These common warehouse challenges can slow down your business, inflate operational costs, and impact customer satisfaction, making it difficult to keep up with growing demand.

It’s time to transform your operations with Autopack’s Warehouse Management System (WMS). Our powerful solution gives you real-time visibility and control over your entire inventory. We help you automate key processes, reduce errors, and ensure seamless order fulfillment from receiving to shipping, turning your warehouse into a model of efficiency.

Get the latest news other tips on business automation by joining our members list.

Features of Warehouse Management System

Pinpoint Inventory Accuracy

Supercharge Order Fulfillment

Slash Operational Costs

Maximize Warehouse Space

Seamless Integration & Scalability

Data-Driven Decision Making

Enhance Customer Satisfaction

How Does Warehouse Management System Works

Goods Receiving

Ensure incoming goods are systematically checked, verified, and entered into your inventory system.

Put Away (Put to Light)

Optimise your warehouse space with put-away solution that uses put-to-light technology, ensuring correct storage location

Inventory Management

Take control of your stock by using a robust inventory management solution, providing real-time visibility into inventory levels.

Cycle Count

Enable continuous and systematic counting of small portions of your inventory by identifying discrepancies and ensure data accuracy.

Order Management

Stay on top of your orders with comprehensive order management seamlessly integrates order processing, tracking, and fulfilment.

Picking (Pick to Light)

Enhance your picking accuracy and speed with pick-to-light solution, guiding workers to the correct items for each order and reducing picking errors.

Packing

Streamline your packing process with intuitive packing solution, designed to maximise efficiency.

Implementation of Warehouse Management System

-

1. Needs Assessment & PlanningStart by defining your goals and pain points with key stakeholders. Assemble a dedicated project team to work with specialists and create a detailed project plan that outlines timelines, responsibilities, and the budget to ensure a clear path forward.

-

2. System Design & ConfigurationAnalyze your physical warehouse layout and map your current processes to the new WMS functionalities. Then, work with the implementation team to customize the system's settings, rules, and workflows to perfectly match your unique operational needs and optimize your space.

-

3. Data Preparation & MigrationBefore going live, it's crucial to clean up your existing inventory data to ensure it's accurate. Once your data is clean, import all the master data, like SKUs and bin locations, into the new WMS to build a strong foundation for the system.

-

4. Hardware & Software IntegrationMake sure all necessary hardware, like scanners and printers, is set up and ready to go. Then, seamlessly connect the new WMS with your other business systems, such as your ERP and e-commerce platforms, to ensure a smooth, real-time flow of information.

-

5. Testing & TrainingConduct thorough testing in a simulated environment to find and fix any issues before launch. At the same time, provide comprehensive training for all staff to ensure everyone is comfortable and proficient with the new system, which is key for a smooth transition.

-

6. Go-Live & Post-Implementation SupportChoose the best go-live strategy and get on-site or remote support during the launch. After going live, continuously monitor the system's performance and work with the support team to optimize and improve it as your business needs evolve over time.

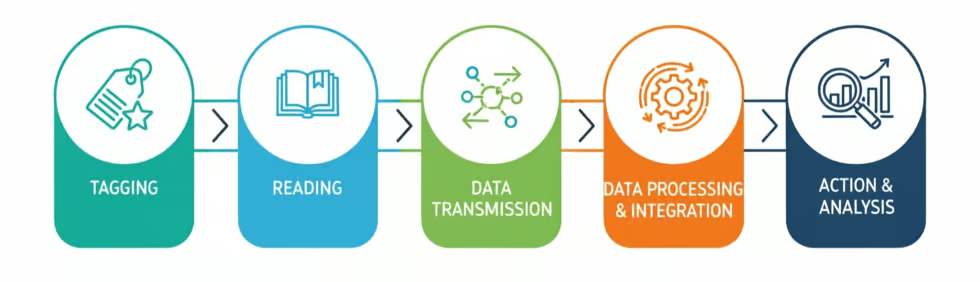

Implementation of Barcode Solution

1. Pick Your Tools

Select the best scanners, printers, and software that fit your needs and work with your current systems.

2. Create Your Barcodes

Select the best barcode style, design a clear layout, and print the labels needed for your items.

3. Buy and Set Up

Purchase the chosen hardware, like scanners and printers, and install everything in the appropriate locations.

4.Connect Your Systems

Connect the new system to your existing software for automatic data sharing and seamless updates.

5. Move Your Data

Carefully transfer product data into the new system, then complete the initial setup and create user accounts.

6. Practice Makes Perfect

Train your team on the new tools, then run tests to identify and fix any potential issues.

7. Go-Live!

Roll out the new barcode system for daily use, and monitor it closely to ensure a smooth start.

8. Ongoing Support and Improvement

Utilize ongoing support and monitor the system to find opportunities for future improvements.

Improvement from using Warehouse Management System

| Feature/Aspect | Before Autopack WMS | After Autopack WMS |

|---|---|---|

| Inventory Accuracy | Frequent discrepancies, manual counts, stockouts/overstocking | Real-time accuracy (99%+) via scanning, optimized stock levels, reduced waste |

| Picking Efficiency | Manual pick lists, inefficient routing, high travel time | Optimized pick paths, wave/zone picking, significant reduction in travel time |

| Order Fulfillment Speed | Slow and error-prone manual processing | Accelerated fulfillment, reduced errors, faster shipping |

| Space Utilization | Suboptimal storage, wasted space | Maximized capacity, optimized slotting, efficient layout management |

| Labor Productivity | Manual tasks, limited visibility into performance | Automated tasks, optimized workflows, improved labor allocation and tracking |

| Data Visibility | Siloed data, limited real-time insights | Centralized data, comprehensive real-time dashboards and reports |

| Error Rate | High risk of human error in receiving, picking, packing | Drastically reduced errors through automation and barcode verification |

| Scalability | Difficult to adapt to growth, requires manual scaling | Easily scalable to handle increased volumes and locations |

| Integration | Disconnected systems (ERP, TMS), manual data transfer | Seamless integration with ERP, TMS, e-commerce platforms |

| Cost of Operations | Higher labor, storage, and error-related costs | Significant reduction in operational costs, improved profitability |

Brands

Contact us to find out more

Use Cases

-

-

Real-Time Location Services

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Inventory Management

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Asset Trackin

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Self-Checkout

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

This is a title

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Patient Tracking

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Asset Identification and Tracking

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

This is a title

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Frequent Asked Questions on Warehouse Management System

-

What is Warehouse Management Software (WMS)?A WMS is a software application designed to help manage and optimize warehouse operations, from the moment goods enter the facility until they are shipped out. It focuses on inventory tracking, order fulfillment, labor management, and space utilization.

-

How does a WMS improve inventory accuracy?A WMS uses technologies like barcode scanning and RFID to track inventory movements in real-time. This eliminates manual errors, provides accurate stock counts, and gives a precise view of item locations, significantly reducing discrepancies.

-

Can WMS integrate with our existing ERP system?Yes, Autopack WMS is designed to integrate seamlessly with various ERP (Enterprise Resource Planning) systems. This integration ensures real-time data synchronization across different business functions like finance, sales, and procurement, avoiding data silos and enhancing overall efficiency.

-

What are the main benefits of implementing a WMS?The main benefits include reduced operational costs, improved inventory accuracy, faster order fulfillment, enhanced customer satisfaction, optimized warehouse space utilization, and better labor productivity.

-

Is Autopack WMS suitable for small and medium-sized enterprises (SMEs)?Yes, Autopack WMS is scalable and designed to cater to businesses of various sizes, including SMBs. Our solutions can be tailored to specific needs and budgets, providing essential features without unnecessary complexity.

-

What types of picking methods does Autopack WMS support?Autopack WMS supports various picking methods, including single order picking, batch picking, zone picking, wave picking, and cluster picking, to optimize efficiency based on your specific operational requirements.

-

How long does a typical WMS implementation take?The duration of a WMS implementation varies depending on the complexity of your operations, the level of customization required, and the scope of integration. A typical implementation can range from a few weeks to several months. Autopack provides a detailed project plan for each client.

-

Does WMS help with labor management?Absolutely. A WMS can optimize labor by guiding workers through the most efficient paths, assigning tasks based on priority and skill, and providing real-time performance metrics, ultimately increasing productivity and reducing labor costs.

-

Is Autopack WMS cloud-based or on-premise?Autopack offers flexible deployment options, including cloud-based (SaaS) and on-premise solutions, to best suit your infrastructure preferences, security requirements, and budget. Cloud-based solutions typically offer greater scalability and lower upfront costs.

-

What kind of reporting and analytics does WMS provide?WMS offers comprehensive reporting and analytics, including KPIs such as order accuracy rates, inventory turnover, shipping timeliness, and labor utilization. These insights help in identifying bottlenecks and making data-driven decisions for continuous improvement.