Logistics Solution

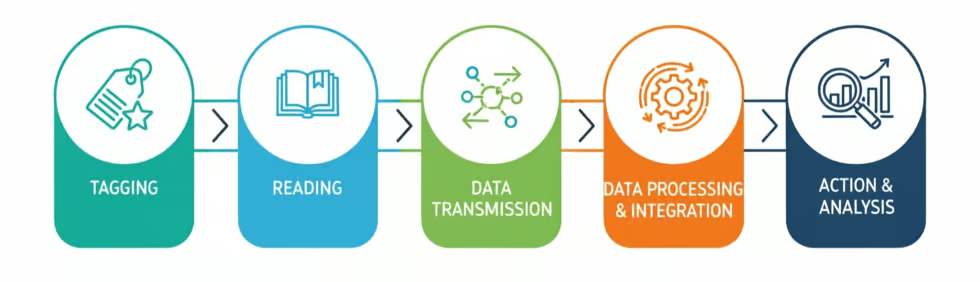

The logistics industry is all about moving goods efficiently. It includes warehousing, transportation, and managing inventory. Autopack offers solutions to streamline these complex processes and improve overall operations.

This industry faces many challenges, like supply chain disruptions and high customer expectations. Autopack understands these issues and helps companies increase visibility and profitability while meeting demands for speed and sustainability.

Get the latest news other tips on business automation by joining our members list.

Features of Logistics Solution

Achieve High Accuracy

Automate and Accelerate Your Throughput

Gain Complete Real-Time Visibility

Integrate Seamlessly with Your WMS

Improve Customer Satisfaction

Enhance Quality Control Automatically

Make Smarter, Data-Driven Decisions

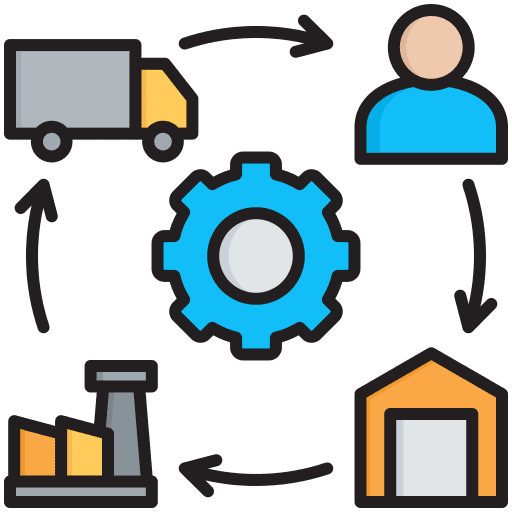

How Does RFID Solution Works

Streamlining Workflows for Logistics

-

Receiving & InboundWhen goods arrive, they are instantly scanned to update your inventory system. Automated vehicles and conveyors then move everything to the correct storage spot, saving time and reducing manual work.

-

Storage & Inventory ManagementSmart tags on items provide a real-time map of your entire inventory. Automated systems store and retrieve goods quickly, while sensors help monitor stock levels and spot misplaced items.

-

Order Picking & FulfillmentWhen an order comes in, the system creates the smartest picking route for staff or robots. Tools like pick-to-light systems ensure accuracy before items are automatically sent to be double-checked and packed.

-

Packing & ShippingAutomated systems pack and seal orders, while smart scales ensure shipping costs are accurate. A final scan instantly creates the shipping label and begins tracking the package for you and your customer.

-

Outbound & Last MileHigh-speed sorters automatically direct each package to the correct delivery truck. Real-time tracking continues as it's loaded, giving you complete visibility all the way to the customer's doorstep.

1. Pick Your Tools

Select the best scanners, printers, and software that fit your needs and work with your current systems.

2. Create Your Barcodes

Select the best barcode style, design a clear layout, and print the labels needed for your items.

3. Buy and Set Up

Purchase the chosen hardware, like scanners and printers, and install everything in the appropriate locations.

4.Connect Your Systems

Connect the new system to your existing software for automatic data sharing and seamless updates.

5. Move Your Data

Carefully transfer product data into the new system, then complete the initial setup and create user accounts.

6. Practice Makes Perfect

Train your team on the new tools, then run tests to identify and fix any potential issues.

7. Go-Live!

Roll out the new barcode system for daily use, and monitor it closely to ensure a smooth start.

8. Ongoing Support and Improvement

Utilize ongoing support and monitor the system to find opportunities for future improvements.

Logistics Solution Comparison

| Feature/Solution | Autopack Integrated AIDC Logistics Solution | Traditional Manual Logistics Operations |

|---|---|---|

| Data Accuracy | Near 100% due to automated scanning/RFID | Prone to human error (5-10% typical) |

| Real-time Visibility | Full, end-to-end real-time tracking | Limited, often delayed or inaccurate |

| Throughput Speed | Significantly increased (2-5x improvement) | Slow, bottlenecked by manual processes |

| Labor Costs | Substantially reduced for repetitive tasks | High, significant reliance on manual labor |

| Inventory Control | Precise, dynamic, and optimized | Inaccurate, leading to over/understocking |

| Scalability | Highly scalable to meet demand fluctuations | Limited scalability, requires more staff |

| Error Traceability | Full audit trails and robust error logging | Difficult to trace errors, blame often unclear |

| Compliance Readiness | Simplified compliance with automated data capture | Manual documentation makes compliance complex |

Brands

Contact us to find out more

Modular Deployment of Autopack Logistics Solutions

-

Warehouse Management System (WMS)

-

Warehouse Management System (WMS)

Optimise inventory and order fulfilment with real-time tracking, automation, and data-driven tools for error-free warehouse operations.

-

Fleet Management System

-

Fleet Management System

Monitor fleet performance, optimise routes, and cut fuel costs with real-time tracking and analytics for efficient resource management.

-

Label Applicator

-

Label Applicator

Automate label placement for high-speed operations, improving accuracy and reducing manual errors to boost packaging efficiency.

-

Dimension, Weight, Scan (DWS) Solution

-

Dimension, Weight, Scan (DWS) Solution

Automate package measurements, weight, and barcode scanning for faster processing and accurate shipment handling.

-

Access Control Solutions

-

Access Control Solutions

Protect assets and secure facilities by restricting access to authorised personnel with customisable and scalable solutions.

-

Inventory Management System

-

Inventory Management System

Track inventory in real time to prevent shortages or overstocking, while analytics-driven insights improve supply chain decisions.

-

Automated Storage and Retrieval System (ASRS)

-

Automated Storage and Retrieval System (ASRS)

Automate goods handling and optimise warehouse space, reducing labour costs and improving storage efficiency.

-

Conveyer Belt System

-

Conveyer Belt System

Simplify material handling with a robust system that improves throughput and operational flow across warehouses.

-

Pick-to-Light/Put-to-Light (PTL) Solution

-

Pick-to-Light/Put-to-Light (PTL) Solution

Guide workers to inventory locations with light signals, streamlining order picking and reducing errors in high-volume centres.

-

Closed-Circuit Television (CCTV)

-

Closed-Circuit Television (CCTV)

Secure logistics facilities with advanced surveillance, offering real-time monitoring and high-definition footage for improved oversight.

-

Order Management System

-

Order Management System

Track orders from placement to delivery, automate manual tasks, and improve customer satisfaction with real-time updates.

-

Automated Guided Vehicles (AGV)

-

Automated Guided Vehicles (AGV)

Increase efficiency with autonomous vehicles that handle material transport and reduce manual labour in busy warehouses.

-

Robotic Arm Palletiser

-

Robotic Arm Palletiser

Track orders from placement to delivery, automate manual tasks, and improve customer satisfaction with real-time updates.

-

Attendance Tracking System

-

Attendance Tracking System

Automate attendance tracking for accurate payroll and better workforce accountability, reducing administrative burdens.

Frequent Asked Questions on Logistics Solution

-

What is AIDC and how does it benefit the Logistics industry?AIDC stands for Automatic Identification and Data Capture. In Logistics, it involves technologies like barcodes, RFID, and vision systems to automatically identify objects, collect data, and input it directly into computer systems. This eliminates manual data entry, reduces errors, improves speed, and provides real-time visibility of goods throughout the supply chain.

-

How long does it take to implement an Autopack Logistics solution?The implementation timeline varies depending on the complexity and scope of the solution. A typical project can range from a few weeks for smaller, focused deployments to several months for large-scale, integrated systems. Autopack works closely with clients to establish realistic timelines and minimize operational disruption.

-

Can Autopack solutions integrate with our existing Warehouse Management System (WMS)?Yes, seamless integration with your existing WMS, ERP, and other critical business systems is a core capability of Autopack solutions. We use various integration methods (APIs, middleware, data exchange protocols) to ensure smooth data flow and interoperability.

-

What kind of ROI can I expect from implementing Autopack’s Logistics solutions?Return on Investment (ROI) can be substantial and multifaceted. Benefits include reduced labor costs, fewer errors and associated rework, optimized inventory levels, increased throughput, improved customer satisfaction, and better compliance. The specific ROI will depend on your current operational inefficiencies and the scope of the implemented solution.

-

Are Autopack’s solutions scalable for growing businesses?Absolutely. Our solutions are designed with scalability in mind. Whether you experience seasonal peaks, expand your product lines, or grow your overall operations, our systems can be adapted and expanded to meet your evolving needs without requiring a complete overhaul.

-

What kind of support does Autopack offer after implementation?Autopack provides comprehensive post-implementation support, including technical assistance, maintenance services, remote monitoring, and ongoing training. We offer various support packages tailored to your specific requirements to ensure long-term system performance and customer satisfaction.

-

How do Autopack solutions address the issue of lost or misplaced inventory?By leveraging real-time AIDC technologies like RFID and advanced WMS integration, our solutions provide precise tracking of every item’s location within your facility. This significantly reduces instances of lost or misplaced inventory, improving accuracy and reducing inventory write-offs.

-

Can Autopack help with compliance and traceability requirements for sensitive goods?Yes, our AIDC solutions are ideal for meeting stringent compliance and traceability requirements. By automatically capturing and linking data to specific items or batches, we enable full audit trails and provide the necessary documentation for regulatory adherence, especially critical for industries like pharmaceuticals or food and beverage within logistics.

-

What is the lifespan of the hardware used in Autopack’s solutions?Autopack utilizes high-quality, industrial-grade hardware designed for durability and longevity in demanding logistics environments. The lifespan can vary by component, but we select equipment known for its reliability and offer maintenance plans to maximize its operational life.

-

How does Autopack ensure data security and privacy?Data security and privacy are paramount. Our solutions incorporate robust security protocols, including encryption, access controls, and secure data transmission methods, to protect your sensitive operational data. We adhere to industry best practices for data management and security.

-

Can Autopack solutions handle varying package sizes and types?Yes, our AIDC and automation solutions are highly versatile. We design systems capable of handling a wide range of package sizes, weights, and types, from small parcels to large pallets, ensuring adaptability to diverse logistics operations.