Healthcare Solution

Autopack provides smart solutions for the healthcare industry. Their systems use automatic identification to improve patient safety and manage inventory. This helps make data more accurate and workflows smoother, so providers can focus on care.

Healthcare operations face many big challenges. Strict rules and the need for accuracy can be tough. Manual work often leads to mistakes and higher costs. Autopack’s solutions help fix these problems by making everything more efficient and easier to track.

Get the latest news other tips on business automation by joining our members list.

Features of Healthcare Solution

Guarantee Patient Safety and Identification

Secure and Accurate Medication Management

Optimize All Medical Assets and Supplies

Streamline Critical Clinical Workflows

Seamlessly Integrate with Your Existing Systems

Achieve Effortless Compliance and Reporting

Reduce Operational Costs and Waste

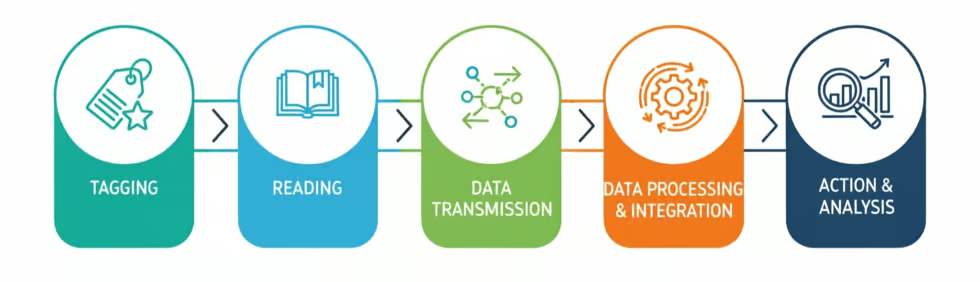

How Does RFID Solution Works

Streamlining Workflows for Better Patient Care

-

Patient Flow & Identification:When a patient arrives, a unique barcode wristband links them to their health record. Staff scan it before any procedure, ensuring the right patient gets the right care every time and preventing dangerous mix-ups.

-

Medication Management & Dispensing:Before giving medicine, a nurse scans the patient's wristband and the medication's barcode. The system instantly confirms it's the correct drug and dose, preventing errors and automatically updating pharmacy inventory.

-

Surgical Instrument Tracking & Sterilization:To ensure surgical tools are sterile and accounted for, each is tagged with a unique code. Scanning at every step creates a complete audit trail, preventing loss and confirming proper sterilization for patient safety.

-

Blood Product Tracking & Transfusion Safety:For a safe blood transfusion, staff scan both the patient’s wristband and the blood bag. The system instantly verifies blood type and compatibility, dramatically reducing the risk of a dangerous transfusion reaction.

-

Pharmacy Inventory & Supply Chain ManagementTo manage its vast inventory, the pharmacy uses automated barcode and RFID tracking. This prevents stockouts and reduces waste from expired drugs, ensuring medications are always available when needed.

1. Pick Your Tools

Select the best scanners, printers, and software that fit your needs and work with your current systems.

2. Create Your Barcodes

Select the best barcode style, design a clear layout, and print the labels needed for your items.

3. Buy and Set Up

Purchase the chosen hardware, like scanners and printers, and install everything in the appropriate locations.

4.Connect Your Systems

Connect the new system to your existing software for automatic data sharing and seamless updates.

5. Move Your Data

Carefully transfer product data into the new system, then complete the initial setup and create user accounts.

6. Practice Makes Perfect

Train your team on the new tools, then run tests to identify and fix any potential issues.

7. Go-Live!

Roll out the new barcode system for daily use, and monitor it closely to ensure a smooth start.

8. Ongoing Support and Improvement

Utilize ongoing support and monitor the system to find opportunities for future improvements.

Brands

Contact us to find out more

Modular Deployment of Autopack Healthcare Solutions

-

Patient Identification and Tracking Solutions

-

Patient Identification and Tracking Solutions

Our patient identification and tracking solutions allow the tracking of patient movements in real time to improve care, enhance safety, and reduce errors.

-

Consumables Utilisation Tracking System

-

Consumables Utilisation Tracking System

Optimise resource use by monitoring consumables, reducing waste, and ensuring critical supplies are always available.

-

Temperature Monitoring System

-

Temperature Monitoring System

Keep sensitive materials safe with continuous temperature tracking and instant alerts to prevent costly mishaps.

-

Visitor Management System

-

Visitor Management System

Ensure secure and seamless visitor access while maintaining detailed digital records for regulatory compliance.

-

Medication Management System

-

Medication Management System

Simplify tracking and dispensing, prevent errors, and ensure patients receive the correct medications at the right time

-

Laboratory Information Management System

-

Laboratory Information Management System

Organise lab processes by tracking samples and test results efficiently, ensuring accuracy and operational ease.

-

Indoor Air Quality (IAQ) Solutions

-

Indoor Air Quality (IAQ) Solutions

Maintain a healthy environment with constant air quality monitoring and timely alerts to address concerns promptly.

-

Closed Circuit Television (CCTV)

-

Closed Circuit Television (CCTV)

Monitor your facility with high-quality surveillance, deter unauthorised access, and review incidents when needed

-

Pharmacy Inventory Control System

-

Pharmacy Inventory Control System

Avoid shortages and waste by tracking inventory levels and expiration dates for seamless medication availability

-

Surgical Instrument Tracking System

-

Surgical Instrument Tracking System

Ensure accountability for surgical instruments, from use to sterilisation, to maintain safety and efficiency.

-

Access Control Solutions

-

Access Control Solutions

Restrict access to sensitive areas with an easy-to-manage system, ensuring only authorised personnel entry.

Frequent Asked Questions on Healthcare

-

What is AIDC, and how does it apply to healthcare?AIDC stands for Automatic Identification and Data Capture. In healthcare, it involves using technologies like barcodes, RFID, and real-time location systems (RTLS) to automatically identify patients, track medications, manage equipment, and streamline data collection, reducing manual errors and improving efficiency.

-

How do Autopack Healthcare Solutions enhance patient safety?Our solutions enhance patient safety by ensuring accurate identification of patients, medications, and specimens through automated scanning. This minimizes the risk of medical errors, such as administering the wrong medication or performing procedures on the wrong patient.

-

What types of assets can be tracked using Autopack healthcare solutions?Autopack solutions can track a wide range of assets, including medical equipment (e.g., infusion pumps, wheelchairs, ventilators), surgical instruments, laboratory samples, and even high-value pharmaceuticals.

-

How does automated inventory management benefit a hospital pharmacy?Automated inventory management reduces stockouts, minimizes waste from expired products, optimizes storage space, and provides real-time visibility into drug levels. This leads to significant cost savings and ensures critical medications are always available.

-

What is the typical implementation timeline for an Autopack healthcare solution?The implementation timeline varies depending on the complexity and scope of the solution. After a detailed discovery and needs assessment, we provide a tailored project plan with clear milestones and timelines.

-

Can Autopack Healthcare Solution track temperature-sensitive medications?Yes, our solutions can incorporate temperature monitoring for cold chain management, ensuring that temperature-sensitive medications are stored and transported under optimal conditions, maintaining their efficacy.

-

What kind of support does Autopack offer after implementation?Autopack provides comprehensive post-implementation support, including technical assistance, maintenance services, and software updates. We also conduct regular reviews to assess system performance and identify opportunities for further optimization.

-

How does Autopack ensure the quality and performance of its RFID solutions?Autopack focuses on providing robust and reliable RFID solutions. While specific details would be provided during a consultation, general practices for quality assurance in RFID solutions include: High-Quality Hardware: Sourcing durable and high-performing RFID tags, readers, and antennas. Autopack is the platinum partner for Zebra, a leading brand in the AIDC. Optimized Software: Developing or integrating with best-in-class software solutions for data processing and management. Expert System Design: Employing experienced engineers to design optimal reader placement and system architecture. Rigorous Testing: Conducting comprehensive testing, including pilot programs, to ensure system accuracy and reliability in real-world conditions. Ongoing Support and Maintenance: Providing continuous technical support, preventive maintenance, and system optimization services to ensure long-term performance.