Electronics Solution

The electronics industry is known for its fast-paced innovation and complex production lines. Manufacturers must manage detailed supply chains and demanding schedules to stay competitive in a global market.

Companies face pressure to boost efficiency, minimize mistakes, and track products closely. Autopack offers smart solutions to meet these challenges, helping to improve transparency and make manufacturing processes run smoothly.

Click Here to View Online Store

Click Here to Contact Us

Get the latest news other tips on business automation by joining our members list.

Features of Electronics Solution

Eliminate Errors with Automated Data Capture

Replace manual tracking with high-speed barcode, RFID, and vision systems. This ensures flawless accuracy when logging every component, circuit board, and finished product, completely eliminating costly data entry mistakes.

Optimize Your Electronics Inventory

Gain real-time visibility into all your stock, from raw components to work-in-progress and finished goods. This prevents production-stopping shortages and costly overstocking, ensuring you have exactly what you need.

Streamline Your Production Line

Integrate Autopack’s solutions directly with your existing manufacturing (MES) and planning (ERP) systems. This provides a complete, live view of your production floor, helping you find and fix bottlenecks for maximum output.

Achieve Complete Product Traceability

Track every component and product from the supplier to the end-user with unique serialization. This is crucial for meeting regulations, managing recalls, and protecting your brand from counterfeit electronics.

Reduce Overall Operational Costs

By minimizing errors, reducing waste, optimizing inventory, and increasing production speed, these solutions directly lead to significant cost savings and improved profitability for your company.

Automate and Enhance Quality Control

Use advanced vision systems to automatically inspect for defects and verify assembly accuracy right on the production line. This helps you catch issues early, reduce expensive rework, and ensure superior product quality.

Boost Workforce Productivity

Automate the tedious tasks of manual scanning and data collection. This frees up your skilled employees to focus on higher-value activities like complex assembly, quality assurance, and process innovation.

Make Smarter, Data-Driven Decisions

Leverage clear dashboards and reporting tools to get actionable insights into your manufacturing performance. This data helps you identify areas for improvement and continuously optimize your entire operation.

Improve Supply Chain Agility

By minimizing errors, reducing waste, optimizing inventory, and increasing production speed, these solutions directly lead to significant cost savings and improved profitability for your company.

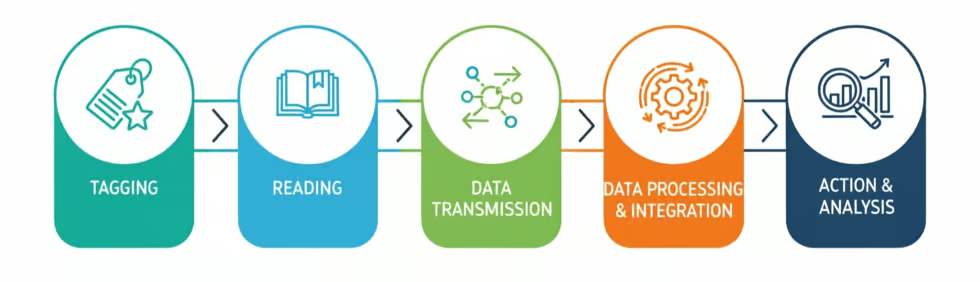

How Does Electronics Solution Works

Streamlining Workflows for Electronics

-

Instant & Accurate Receiving

When new components arrive, they are instantly scanned and logged into your system. This automated process captures all key data, eliminating manual entry errors and ensuring your inventory records are close to 100% accurate from the start. -

Real-Time Production Visibility

Follow every component in real-time as it moves through the assembly line. Our smart scanners provide complete visibility of your production floor, helping you instantly identify bottlenecks and keep your workflow running smoothly. -

Automated Quality Control

Our system automatically inspects products at critical quality checkpoints. If a defect is found, the item is instantly flagged and routed for rework. We track the entire repair process to ensure it meets your highest standards. -

Smart Labeling & Traceability

Once assembled, each product gets a unique digital identity with automated labeling. This links it to its full production history, giving you complete end-to-end traceability from the factory floor all the way to your customer. -

Efficient Warehouse & Shipping

In the warehouse, our system helps you locate and move finished goods with speed and precision. When it’s time to ship, a quick scan updates inventory and generates labels automatically, ensuring fast and error-free dispatch every time.

1. Pick Your Tools

Select the best scanners, printers, and software that fit your needs and work with your current systems.

2. Create Your Barcodes

Select the best barcode style, design a clear layout, and print the labels needed for your items.

3. Buy and Set Up

Purchase the chosen hardware, like scanners and printers, and install everything in the appropriate locations.

4.Connect Your Systems

Connect the new system to your existing software for automatic data sharing and seamless updates.

5. Move Your Data

Carefully transfer product data into the new system, then complete the initial setup and create user accounts.

6. Practice Makes Perfect

Train your team on the new tools, then run tests to identify and fix any potential issues.

7. Go-Live!

Roll out the new barcode system for daily use, and monitor it closely to ensure a smooth start.

8. Ongoing Support and Improvement

Utilize ongoing support and monitor the system to find opportunities for future improvements.

Electronics Solution Comparison

| Feature/Metric | Autopack Automated Solution | Manual Processes (Traditional) |

|---|---|---|

| Data Accuracy | 99.9% (Minimal human error with automated capture) | Prone to human error (manual data entry, transcription mistakes) |

| Inventory Visibility | Real-time, granular tracking of every component and product | Delayed, often inaccurate, reliant on periodic physical counts |

| Production Speed | Significantly increased throughput due to automated tracking and reduced bottlenecks | Slower production cycles due to manual checks and data entry |

| Traceability | End-to-end, item-level traceability for all products | Limited, often batch-level, difficult to pinpoint specific items |

| Labor Costs | Reduced reliance on manual labor for data collection | Higher labor costs associated with data entry and tracking |

| Error Detection | Automated quality checks and immediate error flagging | Relies on manual inspection, often detects errors later |

| Reporting & Insights | Comprehensive, customizable real-time analytics | Basic, often delayed, and fragmented reports |

| Scalability | Easily scalable to accommodate growing production volumes | Difficult to scale without significant increases in labor |

Brands

Contact us to find out more

Modular Deployment of Autopack Electronics Solutions

- RFID Solutions for Manufacturing Execution Systems (MES)

-

RFID Solutions for Manufacturing Execution Systems (MES)

Track components and finished goods in real time with RFID solutions that integrate seamlessly into MES, reducing errors and improving production efficiency.

- Maintenance, Repair, and Operations (MRO) Tracking System

-

Maintenance, Repair, and Operations (MRO) Tracking System

Manage tools and equipment effectively with automated tracking that minimises downtime and ensures essential supplies are always available.

- Visitor Management System

-

Visitor Management System

Enhance facility security by controlling visitor access with quick registration and clear records, ensuring only authorised personnel enter restricted areas.

- Quality Management System – Vision Inspection Solutions for Finished Goods

-

Quality Management System – Vision Inspection Solutions for Finished Goods

Restrict access to sensitive areas with staff access control, safeguarding resources and ensuring a secure environment.

- IoT Sensors for Various Applications (eg. Environment monitoring, IAQ monitoring, Temperature monitoring, etc.)

-

IoT Sensors for Various Applications (eg. Environment monitoring, IAQ monitoring, Temperature monitoring, etc.)

Monitor temperature, air quality, and environmental changes in real time with IoT sensors that provide reliable data for rapid adjustments.

- Permit-to-Work Tracking Solutions

-

Permit-to-Work Tracking Solutions

Automate work permit approvals and ensure safety compliance with a system designed to reduce risks and improve workplace efficiency.

- Warehouse Management System (WMS)

-

Warehouse Management System (WMS)

Streamline inventory, orders, and storage with real-time tracking and analytics to optimise warehouse operations and improve accuracy.

- Access Control Solutions

-

Access Control Solutions

Secure sensitive areas with customisable access rights and comprehensive monitoring to protect assets and maintain operational integrity.

- Indoor Air Quality (IAQ) Solutions for Clean Room Environment

-

Indoor Air Quality (IAQ) Solutions for Clean Room Environment

Maintain cleanroom standards by controlling air conditions, regulating humidity, and filtering contaminants to protect sensitive equipment.

Frequent Asked Questions on Electronics

-

What exactly is AIDC and how does it apply to the Electronic Industry?

AIDC stands for Automatic Identification and Data Capture. In the Electronic Industry, it refers to technologies like barcodes, RFID, and vision systems that automatically identify and collect data about components, products, and assets without human intervention. This data is then fed into your systems for inventory, production, and quality control. -

How quickly can Autopack solutions be implemented in an Electronic Industry facility?

Implementation timelines vary depending on the complexity of your operations, the scope of the solution, and integration requirements. However, Autopack utilizes a structured implementation process that aims for efficient deployment, often ranging from a few weeks to several months for larger projects. We prioritize minimal disruption to your production. -

Are Autopack solutions compatible with our existing ERP and MES systems?

Yes, Autopack solutions are designed for seamless integration with a wide range of existing enterprise systems, including popular ERP (e.g., SAP, Oracle) and MES platforms. Our technical team works closely with you to ensure smooth data exchange and operational compatibility. -

Can Autopack help us meet specific regulatory compliance for product traceability?

Absolutely. Autopack’s robust serialization and traceability features provide granular, end-to-end visibility of your products, helping you meet stringent regulatory requirements common in the Electronic Industry, such as those for component origin or product lifecycle tracking. -

What kind of ROI can we expect from implementing Autopack solutions in the Electronic Industry?

While ROI varies, Electronic Industry clients typically experience significant returns through reduced manual errors, optimized inventory levels, decreased labor costs, improved production throughput, lower rework rates, and enhanced compliance, all contributing to increased profitability. -

Is RFID technology safe to use around sensitive electronic components?

Yes, RFID technology, especially passive RFID, emits very low power and is generally safe for use around most electronic components and sensitive equipment. Our experts can advise on specific frequencies and tag types suitable for your particular applications to ensure no interference. -

How does Autopack handle data security and privacy for collected information?

Our solutions incorporate robust security protocols, including data encryption, access controls, and secure data storage practices, to protect your sensitive operational and product information. -

What kind of training and support does Autopack provide post-implementation?

Autopack offers comprehensive training for your staff to ensure proficiency with the new system. Post-implementation, we provide ongoing technical support, maintenance services, and options for system optimization to ensure your solution continues to perform optimally. -

Can your solutions be scaled as our Electronic Industry production grows?

Yes, Autopack solutions are highly scalable. Whether you’re expanding production lines, adding new facilities, or increasing product volume, our systems can be adapted and expanded to meet your evolving Electronic Industry needs. -

How do Autopack’s vision systems improve quality control in electronics manufacturing?

Our vision systems use high-resolution cameras and advanced image processing algorithms to automatically inspect electronic components, PCBs, and assembled products for defects such as missing components, incorrect placement, solder bridge issues, or surface imperfections, ensuring consistent quality at high speeds. -

What is the benefit of real-time inventory tracking for electronics manufacturers?

Real-time inventory tracking eliminates the guesswork associated with manual counts. It provides accurate, up-to-the-minute data on all raw materials, WIP, and finished goods, preventing stockouts, reducing overstocking, and optimizing cash flow by tying up less capital in inventory. -

How does Autopack address the challenge of managing small, intricate electronic components?

Autopack utilizes advanced AIDC technologies, including high-resolution 2D barcodes and specialized RFID tags designed for very small form factors, combined with precision readers. This allows for accurate identification and tracking of even the most intricate electronic components.