Construction Solution

The construction industry involves complex projects with valuable assets. Managing tools, tracking materials across job sites, and ensuring worker safety are huge challenges that can impact timelines and budgets.

Autopack’s solutions can help by offering clear visibility of your equipment and inventory. This reduces theft, improves site management, and ensures processes run smoothly, helping to keep your projects safe and on track.

Get the latest news other tips on business automation by joining our members list.

Features of Construction Solution

Stop Losing Tools and Equipment

Boost On-Site Productivity

Keep Your Projects On Schedule

Enhance Job Site Safety and Compliance

Streamline Audits Across All Sites

Optimize Your Material Management

Rely on Rugged, Job-Site-Ready Hardware

Automate Asset Check-in and Check-out

Make Smarter, Data-Driven Decisions

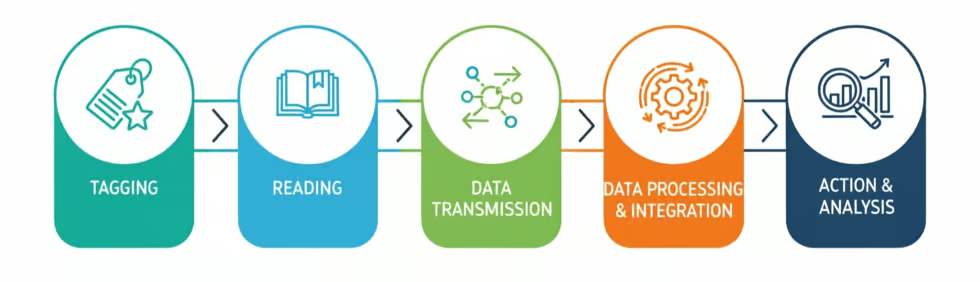

How Does Construction Solution Works

Tagging:

Durable RFID tags or barcode labels are affixed to every asset you want to track—from power drills and ladders to excavators and scaffolding components. Each tag contains a unique identifier.

Scanning & Data Capture:

Workers use rugged handheld scanners or walk through fixed RFID reader portals to capture data. For instance, a worker scans their badge and then scans the tools they are taking from the tool crib. Materials delivered to the site are scanned upon arrival.

Data Transmission:

The captured data is instantly transmitted via Wi-Fi or cellular networks to a central cloud-based or on-premise server. This ensures information is live and accessible immediately.

Centralized Management & Visibility:

Project managers and administrators log into the Autopack software platform via a computer or mobile device. They can view real-time dashboards showing asset locations, who has what equipment, material inventory levels, and upcoming maintenance alerts.

Actionable Insights & Reporting:

The system allows you to generate reports to analyze asset utilization, identify bottlenecks, automate inventory counts, and ensure compliance. For example, you can quickly generate a list of all tools currently assigned to a specific subcontractor.

Streamlining Workflows for Construction

-

Consultation & Site AssessmentWe start by understanding your specific goals and challenges. Our experts visit your job sites and tool cribs to assess your workflow and design the most effective asset tracking solution for your operations.

-

Custom Solution DesignBased on our assessment, we design a custom solution with the right hardware, software, and a clear project timeline. We work with you to set key performance goals to ensure the system delivers the results you need.

-

Tagging Your AssetsWe pre-configure the software with your data and then help your team tag every tool and piece of equipment. We use rugged RFID tags and barcodes built to withstand the tough conditions of any job site.

-

System Installation & IntegrationOur team installs readers at key locations like site entrances and tool cribs. We then ensure the system integrates seamlessly with your existing project management software for a completely unified workflow.

-

On-Site Team TrainingWe provide hands-on training for your entire team, from site managers to crew members. Our goal is to make sure everyone is confident using the new system to track assets effectively from day one.

-

Go-Live & Ongoing SupportWe are on-site during launch to ensure a smooth start and provide immediate support. Our partnership continues long-term with technical assistance and system updates to help your construction projects succeed.

1. Pick Your Tools

Select the best scanners, printers, and software that fit your needs and work with your current systems.

2. Create Your Barcodes

Select the best barcode style, design a clear layout, and print the labels needed for your items.

3. Buy and Set Up

Purchase the chosen hardware, like scanners and printers, and install everything in the appropriate locations.

4.Connect Your Systems

Connect the new system to your existing software for automatic data sharing and seamless updates.

5. Move Your Data

Carefully transfer product data into the new system, then complete the initial setup and create user accounts.

6. Practice Makes Perfect

Train your team on the new tools, then run tests to identify and fix any potential issues.

7. Go-Live!

Roll out the new barcode system for daily use, and monitor it closely to ensure a smooth start.

8. Ongoing Support and Improvement

Utilize ongoing support and monitor the system to find opportunities for future improvements.

Construction Solution Comparison

| Feature/Metric | Autopack Automated Solution | Manual Processes (Traditional) |

|---|---|---|

| Data Accuracy | 99.9% (Minimal human error with automated capture) | Prone to human error (manual data entry, transcription mistakes) |

| Inventory Visibility | Real-time, granular tracking of every component and product | Delayed, often inaccurate, reliant on periodic physical counts |

| Production Speed | Significantly increased throughput due to automated tracking and reduced bottlenecks | Slower production cycles due to manual checks and data entry |

| Traceability | End-to-end, item-level traceability for all products | Limited, often batch-level, difficult to pinpoint specific items |

| Labor Costs | Reduced reliance on manual labor for data collection | Higher labor costs associated with data entry and tracking |

| Error Detection | Automated quality checks and immediate error flagging | Relies on manual inspection, often detects errors later |

| Reporting & Insights | Comprehensive, customizable real-time analytics | Basic, often delayed, and fragmented reports |

| Scalability | Easily scalable to accommodate growing production volumes | Difficult to scale without significant increases in labor |

Brands

Contact us to find out more

Modular Deployment of Autopack Construction Solutions

-

Workforce Safety & Management

-

Workforce Safety & Management

Keep your team safe with smart access control that checks for proper safety gear. You can also track worker locations in real-time on large sites. This improves coordination and allows for a rapid response during any emergencies

-

Asset & Equipment Management

-

Asset & Equipment Management

Never lose a tool again! Tag everything from power drills to generators. The system automates check-ins and check-outs, prevents theft, and alerts you when equipment is due for maintenance, keeping your project on schedule.

-

Materials & Inventory Control

-

Materials & Inventory Control

Easily manage large materials like steel beams and precast concrete in your yard. Our system helps you locate items instantly, reducing search time. This ensures everything is ready for installation right when you need it.

-

Site Security & Monitoring

-

Site Security & Monitoring

Get a complete, 24/7 view of your construction site. This module uses advanced CCTV systems to deter theft and monitor progress. You can also add drone surveillance for a bird's-eye view of the entire project area.

-

Environmental Monitoring

-

Environmental Monitoring

Create a safer worksite by monitoring noise, dust, and weather conditions with smart sensors. This helps you protect your workers and the surrounding community while ensuring you meet environmental regulations.

-

Smart Waste Management

-

Smart Waste Management

Keep your site green by tracking waste and recycling. Tags on bins can monitor when they are full and ensure materials are sorted correctly. This helps you meet environmental goals and can even reduce disposal costs.

-

Fleet & Heavy Machinery Logistics

-

Fleet & Heavy Machinery Logistics

Manage your large vehicles like cranes and excavators more efficiently. You can track fuel usage, schedule maintenance automatically, and monitor engine hours. This helps reduce downtime and keeps your heavy fleet running smoothly.

-

Automated Emergency Mustering

-

Automated Emergency Mustering

Ensure everyone is safe during an emergency. The real-time location tracking system can automatically check workers in at designated safety zones. This gives you an instant and accurate headcount when every second counts.

-

Digital Quality Control Checkpoints

-

Digital Quality Control Checkpoints

Create a flawless quality assurance trail from start to finish. You can place checkpoints at key construction stages to digitally verify inspections and approvals. This ensures no step is missed and provides a complete record for compliance.

Frequent Asked Questions on Construction

-

How durable are the RFID tags and barcode labels in a harsh construction environment?Our tags and labels are specifically designed for the Construction industry. We offer a range of options, including hard-cased, over-molded, and encapsulated tags that are resistant to impact, water, dust, chemicals, and extreme temperatures, ensuring a long and reliable lifespan.

-

Can this system integrate with our existing project management or accounting software?Yes. Our software is designed for flexibility and can be integrated with many popular ERP, accounting, and project management systems via APIs. This allows for seamless data flow, eliminating the need for double entry and enhancing your existing software’s capabilities.

-

What is the typical range of an RFID reader on a construction site?The read range depends on the type of RFID technology used (Passive UHF, Active, etc.) and the environment. Handheld readers can typically capture tags from several meters away, while fixed portals can cover wider areas like gates or doorways. We conduct a site assessment to determine the optimal hardware for your specific layout.

-

How much time does it take to perform a full site inventory with this system?What previously took days of manual counting can now be accomplished in just a few hours. A worker can simply walk or drive through the site with a handheld RFID reader, which automatically captures data from hundreds of tagged items per minute without a direct line of sight.

-

Will my team need extensive technical training to use the system?No. The system is designed to be user-friendly. The handheld devices are as intuitive as a smartphone, and the software dashboard is clear and straightforward. We provide comprehensive, hands-on training to ensure your team is confident and proficient from day one.

-

Can the system differentiate between multiple construction sites?Absolutely. The software platform allows you to manage assets across multiple projects and locations. You can transfer assets between sites and maintain a clear, centralized view of your entire company’s asset pool in real-time.

-

How does the system improve worker accountability?By linking assets to an employee ID during the check-out process, the system creates an indisputable digital record of who is responsible for each tool or piece of equipment. This significantly reduces “finger-pointing” and encourages workers to take better care of company property.

-

What is the return on investment (ROI) for a Construction solution?The ROI is typically realized through a combination of factors: dramatic reduction in tool and equipment replacement costs, increased labor productivity (less time searching), elimination of project delays due to missing items, and lower administrative overhead for asset management. Most clients see a positive ROI within the first 12-18 months.

-

Can the system be used to track bulk materials like sand or gravel?While individual grains of sand cannot be tagged, the system is highly effective for managing consumable materials. Barcodes can be used on pallets or delivery dockets to track receipt and consumption, providing better inventory control than manual logs.

-

What kind of support does Autopack offer after installation?We offer a comprehensive support package that includes a dedicated help desk, remote technical support, software updates, and options for on-site assistance. Our goal is to be your long-term partner in operational efficiency.