Asset Tracking & Inventory Control System (Trak-it) Overview

It is important to have proper inventory control system such as Asset Tracking & Inventory Control System (Trak-it) as it helps businesses manage their stock levels efficiently, ensuring they have the right products in the right quantities at the right time. It tracks the movement of goods from arrival to shipment, preventing stockouts and overstocking, which ultimately maximizes profits and saves resources. This type of software provides real-time visibility into inventory across multiple locations, streamlines operations, and automates many manual tasks associated with stock management.

Get the latest news other tips on business automation by joining our members list.

Features of Asset Tracking & Inventory Control System (Trak-it)

Achieve Pinpoint Inventory Accuracy

Optimize Stock Levels Intelligently

Boost Operational Efficiency

Gain Real-Time Visibility and Insights

Enhance Customer Satisfaction

Slash Costs and Reduce Waste

Scale and Integrate with Ease

Master Traceability and Compliance

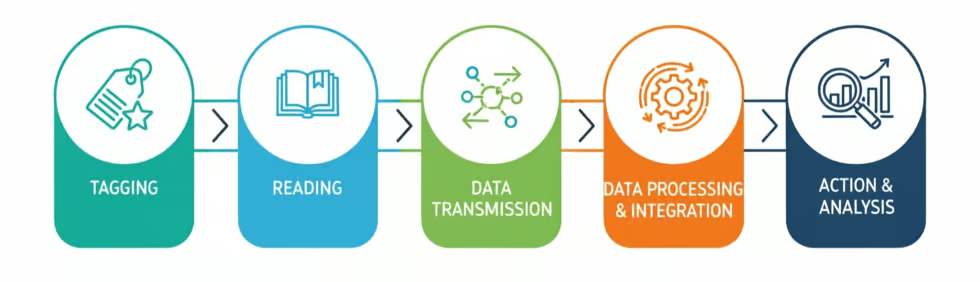

How Does Asset Tracking & Inventory Control System (Trak-it) Works

Implementation of Trak-it: Asset Tracking & Inventory Control System

-

1. Discovery and DesignFirst, we dive into your current workflow to understand your unique challenges and goals. We then design a system blueprint that outlines key features, hardware needs, and how Trak-it will integrate with your existing software.

-

Project PlanningNext, we create a detailed project plan. This roadmap includes clear timelines, milestones, and a defined budget, ensuring everyone is aligned and knows what to expect. We'll also set key metrics to measure success.

-

3. System Setup and TestingWhether we're building a custom solution or configuring our software, this is where we bring your system to life. We set up all your business rules and workflows, followed by rigorous testing to ensure everything runs perfectly.

-

4. Data MigrationWe carefully move your existing inventory data from spreadsheets or old systems into Trak-it. Our team cleans and formats the data to guarantee a smooth and accurate transition, so you can hit the ground running.

-

5. Seamless IntegrationTo create a truly connected system, we integrate Trak-it with your other essential business tools, like accounting or e-commerce platforms. This eliminates manual data entry and ensures a seamless flow of information across your company.

-

6. Team TrainingWe provide comprehensive training for your entire team to ensure everyone is confident using the new system. Our sessions cover all functionalities and best practices to help your staff work efficiently from day one.

-

7. Go-Live!This is the exciting part—we officially launch your new Trak-it system! We typically use a phased rollout to ensure a smooth transition with minimal disruption to your daily operations.

-

8. Ongoing Support & OptimizationOur partnership doesn't end at launch. We provide continuous support to address any questions and monitor system performance. We use your feedback to make ongoing improvements, ensuring Trak-it always meets your needs.

1. Pick Your Tools

Select the best scanners, printers, and software that fit your needs and work with your current systems.

2. Create Your Barcodes

Select the best barcode style, design a clear layout, and print the labels needed for your items.

3. Buy and Set Up

Purchase the chosen hardware, like scanners and printers, and install everything in the appropriate locations.

4.Connect Your Systems

Connect the new system to your existing software for automatic data sharing and seamless updates.

5. Move Your Data

Carefully transfer product data into the new system, then complete the initial setup and create user accounts.

6. Practice Makes Perfect

Train your team on the new tools, then run tests to identify and fix any potential issues.

7. Go-Live!

Roll out the new barcode system for daily use, and monitor it closely to ensure a smooth start.

8. Ongoing Support and Improvement

Utilize ongoing support and monitor the system to find opportunities for future improvements.

Barcode vs RFID

| Feature/Solution | Autopack RFID Solutions | Barcode Scanning |

|---|---|---|

| Data Capture | Automated, real-time, bulk reading | Manual, one-by-one, line-of-sight required |

| Line of Sight | Not required | Required |

| Read Speed | Very high (hundreds of items simultaneously) | Low (single item at a time) |

| Accuracy | High (up to 98-99%) | Moderate (prone to human error) |

| Inventory Management | Dynamic, precise, real-time updates | Static, periodic, labor-intensive |

| Labor Efficiency | Extremely high (automation) | Low (manual scanning and data entry) |

| Error Rate | Very low (automated) | Moderate to High (manual processes) |

| Durability | Tags highly durable, resistant to environment | Barcodes can be easily damaged, smudged |

| Traceability | Excellent, end-to-end, granular | Good, but often limited to scanning points |

| Data Storage | High (can store more info) | Low (limited to numeric/alphanumeric code) |

| Security Features | Enhanced with unique IDs, anti-tamper options | Limited to visual inspection |

| Scalability | High (easily scalable to large operations) | Moderate (scaling requires more manual effort) |

| Cost of Ownership | Moderate to High (initial investment, lower ongoing) | Low (initial investment, higher ongoing labor) |

Brands

Contact us to find out more

Use Cases

-

-

Manufacturing

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Inventory Management

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Asset Trackin

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Self-Checkout

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

This is a title

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Patient Tracking

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

Asset Identification and Tracking

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

-

-

This is a title

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Frequent Asked Questions on

Trak-it: Asset Tracking & Inventory Control System

-

What is inventory control software?Inventory control software is a digital system that helps businesses manage and track their stock of products, raw materials, and supplies across various locations, from the moment they arrive to when they are shipped or used. It aims to optimize stock levels, reduce costs, and improve operational efficiency.

-

How does inventory control software differ from asset tracking software?While both track items, inventory control software primarily manages goods intended for sale or used in production (inventory), focusing on their flow, quantity, and reorder points. Asset tracking software, on the other hand, monitors fixed assets (e.g., equipment, tools, furniture) that a company uses internally to run its business, focusing on their location, usage, maintenance, and lifecycle. Autopack offers solutions that can bridge both needs.

-

What are the key benefits of using inventory control software?The main benefits include improved inventory accuracy, reduced stockouts and overstocking, significant cost savings, increased operational efficiency, better data-driven decision-making, faster order fulfillment, enhanced customer satisfaction, and simplified compliance and traceability.

-

Can this software integrate with my existing business systems?Yes, most modern inventory control software, including Autopack’s solutions, are designed to integrate seamlessly with other essential business systems such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), accounting software (e.g., QuickBooks), and e-commerce platforms. This ensures synchronized data flow and a unified view of your operations.

-

Is real-time inventory tracking possible?Absolutely. A core feature of effective inventory control software is real-time tracking, often facilitated by barcode scanning, RFID technology, or other automated data capture methods. This provides up-to-the-minute updates on stock levels and movements.

-

How does the software help with demand forecasting?The software is typically designed for multi-location inventory management, providing a centralized dashboard to view and manage stock across all your facilities. This includes tracking transfers between locations and consolidating inventory data.

-

What happens if I have multiple warehouses or store locations?The software is typically designed for multi-location inventory management, providing a centralized dashboard to view and manage stock across all your facilities. This includes tracking transfers between locations and consolidating inventory data.

-

How does inventory control software reduce costs?It reduces costs by minimizing overstocking (reducing carrying costs, storage fees, and risk of obsolescence), preventing stockouts (avoiding lost sales and rush shipping fees), automating manual tasks (reducing labor costs), and providing data to negotiate better terms with suppliers.

-

Is user training required for our staff?Yes, user training is a crucial part of the implementation process. Comprehensive training ensures that your staff can effectively use all the features of the software, maximizing its benefits and minimizing errors.

-

What kind of reports can I generate with this software?You can generate a wide range of reports, including inventory valuation reports, stock movement reports, sales analysis by product, slow-moving or obsolete inventory reports, purchase order reports, and cycle count variances. These reports provide valuable insights for strategic planning.

-

How long does it take to implement inventory control software?The implementation timeline varies depending on the complexity of your business, the size of your inventory, the level of customization required, and the extent of integrations. It can range from a few weeks for simpler solutions to several months for comprehensive enterprise-level systems.

-

Does it support barcode and RFID scanning?Yes, most advanced inventory control solutions support barcode scanning and often RFID technology for efficient, accurate, and rapid data capture during receiving, picking, shipping, and physical counts